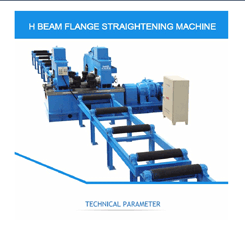

Karam machine tools “Flange Straightening Machines” are designed to straighten flanges on H and I Beams. The machine is designed horizontally to handle large and heavy beams at ease. Salient features of the machine include strong straightening force, large straightening range, high quality, and fine finish.

This machine use to remove the deformation in the flanges that occur during welding.

Machine consists of infeed conveyors to feed the beam in the “i” (vertical) position, flange straightening station with hydraulic press rollers & web guide rollers and outfeed conveyors.

lh and rh side flanges straightened simultaneously.

Straightening Speed: 6m/min, based on the thickness of the flange and amount of bend, the straightening speed vary.

Material: e 250 & e 350 grade plates can be straightened.

Optional beam 180-degree tilter to flip upside – down can be provided.

Hydraulically operated flange straightening machine

Models:

| Model | KMT40B | KMT60C | KMT60D | KMT80B |

|---|---|---|---|---|

| Flange Width | 200~800mm | 200~1000mm | 200-800mm | 200~1000mm |

| Flange Width | 200~800mm | 200~1000mm | 200-800mm | 200~1000mm |

| Flange thickness | <40mm | <60mm | <60mm | <80mm |

| Minimum web Height | 350mm | 350mm | 200mm | 380mm |

| Material of plate | Q235-A | Q345(16Mn) | Q235-A | Q345(16Mn) |

| Staightening Speed | 9m/min | 6.28m/min | 9.8m/min | 6.1m/min |

| Total Power | 13.2kW | 16.5kW | 21kW | 22kW |