The Evolution and Excellence of Vertical Turning Lathe Machines in India

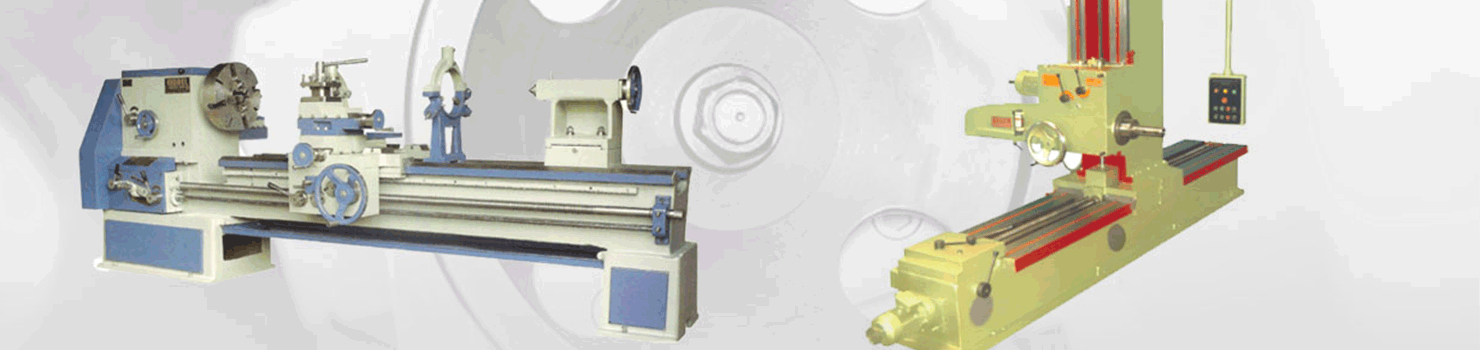

The effectiveness and accuracy of operations are greatly influenced by the equipment and technology utilized in the dynamic field of production. The Vertical Turning Lathe equipment is a highly versatile and efficient equipment among the many others that are available. This blog examines the importance of vertical turning lathe Machine in India, contrasts with end milling machine in India and horizontal boring machines, and demonstrates why Karam Machine Tools should be your first choice for superior machinery.

Recognizing Vertical Turning Lathe Equipment

Turning Vertically Large, heavy workpieces are machined using specialized tools called lathes. Vertical lathes function with the spindle oriented vertically, in contrast to their horizontal counterparts. This design improves stability during machining and makes it simpler to load and unload workpieces.

Characteristics and Advantages

Enhanced accuracy: The great accuracy provided by vertical turning lathes is essential for creating intricate pieces with exacting tolerances. The spindle’s vertical orientation reduces deflection, which improves precision.

Versatility: These tools are appropriate for both rough and finish machining, and they can handle a wide range of materials. They are essential in sectors including heavy machinery, aircraft, and the automobile industry because of their capacity to handle big, heavy workpieces.

Enhanced Safety: By guaranteeing that the workpiece is held securely, the vertical design lowers the possibility of accidents. Because the operator may operate at a comfortable height, their position is also safer.

Comparing Other Machinery with Vertical Turning Lathe Machines

Understanding how Vertical Turning Lathe Machines compare to other machinery types, such as Horizontal Boring Machines and End Milling Machines, is crucial to properly appreciating their benefits.

Machines for Horizontal Boring

The main purpose of horizontal boring machines is to drill big, accurate holes in workpieces. Specifically, their spindle direction is horizontal, which makes them perfect for boring big, heavy components.

Principal Disparities:

Spindle Orientation: Horizontal Boring Machines employ a horizontal spindle in contrast to Vertical Turning Lathes, which have a vertical spindle. Turning is not as appropriate for this design as boring operations are.

Applications: Vertical Turning Lathe machine in India is more adaptable than Horizontal Boring Machines, as they can do drilling, turning, and milling tasks.

Workpiece Handling: Horizontal Boring Machines may require supplementary support systems for handling large and heavy workpieces; Vertical Turning Lathes make this easier.

End Milling Devices

End milling machines employ a revolving tool to cut and shape materials. They are necessary to create intricate, multifaceted forms and features.

Principal Disparities:

Machining Process: Vertical Turning Lathes are made for turning activities, whereas End Milling Machines concentrate on cutting and shaping.

Tool Orientation: Depending on the setup, end milling machines employ a revolving tool in a horizontal or vertical position, whereas vertical turning lathes use a rotating tool in a vertical orientation.

Applications: While Vertical Turning Lathe machine offers a wider range of applications, such as drilling and turning, End Milling Machines are best suited for precise cutting.

Why Select Tools From Karam Machine?

One of the top brands in high-quality machinery manufacture is Karam Machine Tools, which produces end milling machines, horizontal boring machines, and vertical turning lathe machines. Consequently, this is what makes Karam Machine Tools unique:

1. Superior Quality

At Karam Machine Tools, quality is our top priority. Our Vertical Turning Lathe Machines are built using the latest technology and high-grade materials to ensure durability and precision. We adhere to stringent quality control measures to deliver equipment that meets international standards.

2. Innovation and Technology

We invest in research and development to stay at the forefront of technological advancements. We equip our Vertical Turning Lathes with state-of-the-art features that enhance performance and efficiency. Whether you’re looking for advanced controls or precision engineering, Karam Machine Tools has you covered.

3. Comprehensive Support

Our commitment to customer satisfaction goes beyond just providing top-notch machinery. Additionally, we offer comprehensive support and after-sales service to ensure that your equipment operates at its best. Furthermore, our team of experts is always available to assist with installation, maintenance, and repairs.

4. Custom Solutions

Understanding that every manufacturing process is unique, we offer customized solutions tailored to your specific needs. Whether you require modifications to our standard Vertical Turning Lathes or need a specific configuration, Karam Machine Tools can deliver a solution that fits your requirements.

In summary

Selecting the appropriate machinery is essential for obtaining the best outcomes in the highly competitive industrial sector. India’s vertical turning lathe machines are a vital asset in many industries because of their unmatched precision and adaptability. Although end milling machines and horizontal boring machines have their uses, the vertical turning lathe stands out because of its ease of handling massive and intricate workpieces.

Karam Machine Tools is committed to offering top-notch, cutting-edge equipment that satisfies the needs of contemporary production. We are your reliable partner for vertical turning lathe machines, horizontal boring machines, and end milling machines because we place a strong emphasis on quality, technology, and customer service. When looking for equipment that offers excellence, dependability, and performance, choose Karam Machine Tools.