Introduction

In precision engineering, choosing the appropriate equipment is essential to getting the best possible manufacturing results. In this operation, horizontal boring machine is crucial piece of equipment that work in tandem with other necessary tools like end milling machines and vertical turning lathe machines. Karam Machine Tools is a leading provider of cutting-edge solutions for many industrial applications. This blog examines the significance of these devices and demonstrates the excellent goods that Karam Machine Tools produces.

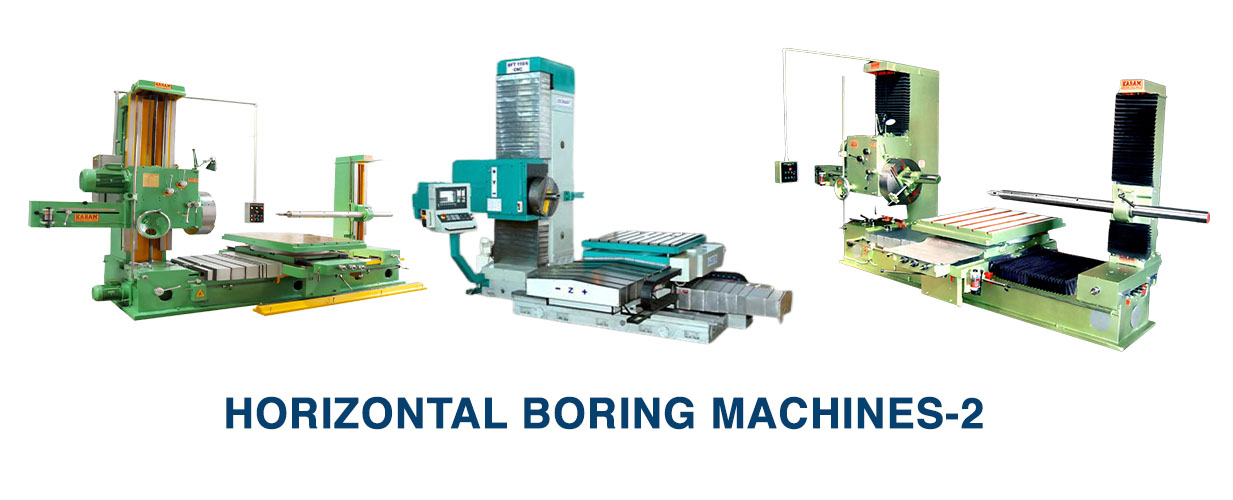

Comprehending Horizontal Boring Equipment

A vital equipment in the manufacturing industry, the Horizontal Boring Machines are recognized for its accuracy and adaptability. The horizontal orientation of an HBM’s spindle, in contrast to that of vertical boring machines, enables it to precisely handle massive, heavy workpieces. This orientation is especially useful for jobs that call for accurate milling, drilling, and boring of large components.

Boring Horizontally Numerous industries, such as aerospace, automotive, and heavy engineering, use machines. They are invaluable due to their capacity for handling big workpieces and high-precision machining. You can use them, for instance, for complex operations like drilling, tapping, and facing, which reduces the need for multiple pieces of equipment and speeds up the manufacturing process.

A well-known brand in the sector, Karam Machine Tools is recognized for producing high-quality horizontal boring machines. We design our machines to meet the highest industry requirements for precision, durability, and performance. This guarantees that consumers can count on Karam’s equipment to deliver reliable, excellent outcomes every time.

Crucial Elements of Horizontal Boring Equipment

Table: A movable table is used to attach the workpiece at different angles and positions. This adaptability is necessary to get precise machining outcomes.

Spindle: The spindle rotates quickly to carry out a variety of tasks while holding the cutting tool. The horizontal spindle position in HBMs is perfect for big component machining.

Column: During operations, the column provides stability by supporting the spindle and table. It contains the mechanics that allow the spindle and table to move precisely.

Cross Rail: The cross rail enables vertical table movement, making it easier to precisely position and adjust the workpiece.

Benefits of Horizontal Boring Equipment

For many industrial applications, horizontal boring machines are the favored option because of their numerous advantages.

High Accuracy and Precision: High degrees of accuracy and precision are intended to be provided by HBMs. Because of the improved control over the machining process made possible by the spindle’s horizontal orientation, the final products are of higher quality.

Versatility: These devices are capable of a large number of tasks, such as milling, boring, and drilling. They are appropriate for several industries, including the automotive and aerospace ones, due to their adaptability.

Ability to Handle Big Components: The ability of HBMs to handle big, heavy workpieces is one of its biggest advantages. For sectors that deal with large components and need accurate machining, this skill is crucial.

Enhanced Surface Finish: HBMs’ stiffness and stability help machined products have better surface finishes. This is especially crucial for parts that need to be smooth and have a lot of detail.

Horizontal Boring Machine Applications

Applications for horizontal boring machines can be found in a wide range of industries:

Aerospace Industry: HBMs are utilized in the aerospace industry to precisely machine huge aircraft components. They are perfect for this industry because of their capacity to manage intricate geometries and close tolerances.

Automotive Industry: When it comes to machining engine blocks, transmission cases, and other major components, the automotive industry benefits from the accuracy and versatility of HBMs.

Construction and Heavy Equipment: We use HBMs to mill large components such as gears, shafts, and housings for construction and heavy equipment.

Selecting the Appropriate Device for Your Purposes

When choosing the right machining equipment, you must consider factors such as the nature of the workpieces, the level of precision needed, and the volume of production. Horizontal Boring Machines are frequently the best option for huge, intricate components requiring a high degree of precision. However, End Milling Machine in India and Vertical Turning Lathe Machines could be better appropriate for jobs involving smaller parts or specialized activities like milling or turning.

Conclusion

Precision machining requires the use of horizontal boring machines, which are essential equipment. They are an invaluable tool to many different businesses because of their remarkable accuracy in handling massive and complex components. Even if they have many benefits, for some jobs and needs you need to take into account other machines like Vertical Turning Lathe Machines and End Milling Machines. Businesses can make well-informed judgments and attain optimal outcomes in their machining processes by comprehending the advantages and uses of each kind of machine.

Contact us directly or visit our website for more details about our offerings. Allow us to assist you in locating the ideal answer to your machining needs.